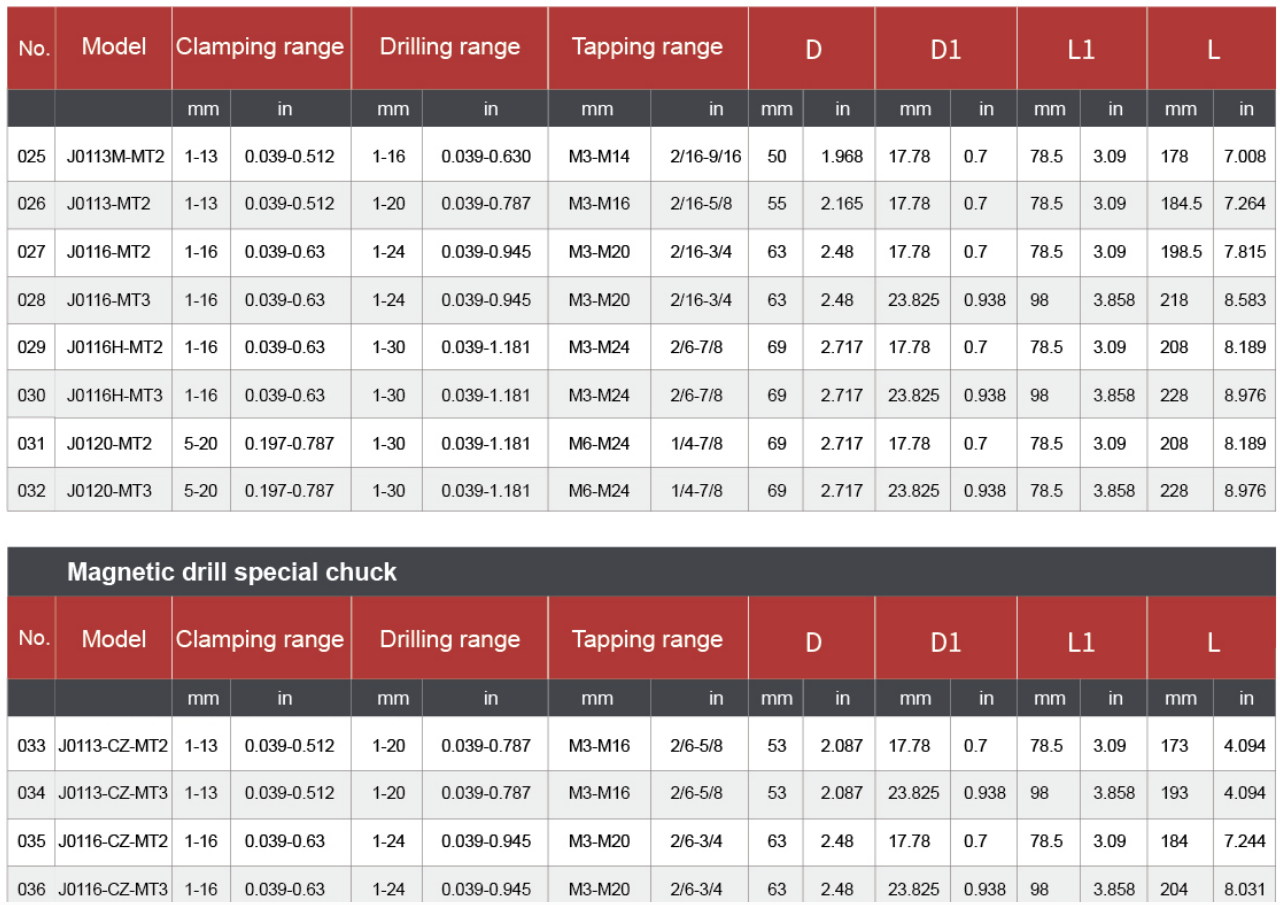

| imodeli | Ibanga lokubamba | Ibanga lokubhoboza | Ukuthepha ububanzi | D | D | L1 | L | |||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | |

| I-J0113M-C20 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | i-M3-M16 | 1/16-5/8 | 50 | 1.968 | 20 | 0.787 | 60 | 2.362 | 159 | 6.26 |

| J0113-C20 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | i-M3-M24 | 1/16-7/8 | 55 | 2.165 | 20 | 0.787 | 60 | 2.362 | 166 | 6.535 |

| J0116-C20 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | i-M3-M24 | 1/16-7/8 | 63 | 2.48 | 20 | 0.787 | 60 | 2.362 | 180 | 7.887 |

| J0116-C25 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | i-M3-M24 | 1/16-7/8 | 63 | 2.48 | 25 | 0.984 | 80 | 3.15 | 200 | 7.874 |

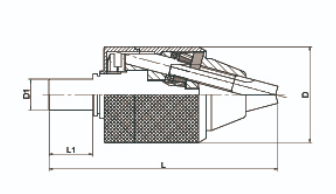

I-taper mount tapping kanye nokubhoboza ama-chucks aziqinisayo angamathuluzi akhethekile asetshenziselwa ukubamba nokuvikela izingcezu zokubhola kanye nompompi endaweni ngesikhathi sokusebenza komshini.Lawa ma-chuck ayizingxenye ezibalulekile zanoma yikuphi ukusethwa kwemishini futhi asetshenziswa kakhulu ezimbonini ezahlukahlukene, ezifaka i-aerospace, eyezimoto, kanye neyokukhiqiza.

Idizayini ye-taper mount chuck isuselwe kusistimu ye-Morse taper, okuyindlela emisiwe yokuvikela amathuluzi emshinini wokuphotha.I-taper mount chuck ifaka i-taper yesilisa edizayinelwe ukuthi ilingane kahle ne-taper yesifazane emshinini wokuphotha.Lokhu kunikeza uxhumano oluphephile noluzinzile oluqinisekisa ukuqondanisa kwamathuluzi okunembayo futhi lunciphise ukuphela kwamathuluzi.

Enye yezinzuzo ezibalulekile zama-taper mount chucks ukuguquguquka kwawo.Lawa ma-chuck angabamba osayizi ababanzi bamathuluzi nomumo, okuhlanganisa izingcezu zokubhoboza, ompompi, ama-reamers, nezigayo zokugcina.Lokhu kubenza bafaneleke ezinhlobonhlobo zezinhlelo zokusebenza zemishini, kusukela ekubholeni nasekuthepheni kuye ekubholeni nasekugayeni.

Ama-chuck e-Taper mount adume ngokuhlala kwawo nokwethembeka ngaphezu kokuvumelana nezimo nokuba lula kwawo.Ukubekezelela izimfuno zomsebenzi womshini osindayo, lawa ma-chucks ngokuvamile akhiwa ngezinto zekhwalithi ephezulu njengensimbi eqinile noma i-carbide.Futhi zidinga ukunakekelwa okuncane kanye nokunakekelwa ukuze kugcinwe ukusebenza okuhlala isikhathi eside.

Ukuze ugweme ukuphela kwethuluzi futhi wehlise amathuba okulimala kwe-chuck noma umshini wokuphotha ngenkathi usebenzisa i-taper mount chuck, kubalulekile ukuqinisekisa ukufakwa nokuqondanisa kwethuluzi elifanele.Ukuze wenze lokhu, ithuluzi livamise ukufakwa ngobumnene ku-chuck futhi imihlathi ye-chuck iyaqiniswa ukuze ithuluzi libambe endaweni.Ukwengeza, kubalulekile ukuhlola njalo i-chuck ukuthi igugile futhi ilimele futhi ubuyisele noma yiziphi izingxenye ezigugile noma ezilimele njengoba kudingeka.

Ukuze ugweme ukuphela kwethuluzi futhi wehlise amathuba okulimala kwe-chuck noma umshini wokuphotha ngenkathi usebenzisa i-taper mount chuck, kubalulekile ukuqinisekisa ukufakwa nokuqondanisa kwethuluzi elifanele.Ukuze wenze lokhu, ithuluzi livamise ukufakwa ngobumnene ku-chuck futhi imihlathi ye-chuck iyaqiniswa ukuze ithuluzi libambe endaweni.Ukwengeza, kubalulekile ukuhlola njalo i-chuck ukuthi igugile futhi ilimale bese ushintsha noma yiziphi izingxenye ezigugile noma ezilimele njengoba kudingeka.

Ngokuvamile, ukuziqinisa kwe-taper mount tapping kanye ne-drilling chucks kuyimishini edingekayo yanoma iyiphi inqubo yokwenza imishini.Ukuvumelana nezimo nokuqina kwazo kuzenza ziphelele ezinhlelweni ezihlukahlukene zezinhlelo zokusebenza, futhi zinikeza uxhumano oluphephile noluthembekile lwamathuluzi ahlukahlukene. ukuqinisekisa ukusebenza okuthembekile nokungaguquguquki eminyakeni ezayo.